In any hospital, the "last 100 meters" of the medication journey—the physical path from the pharmacy to the patient's bedside—is the most fraught with risk.

For decades, this workflow has been dangerously fragmented. The process is familiar: a central pharmacy dispenses a patient's 24-hour supply of medication, often in a bag or vial. This is sent to the nursing unit, where a nurse must manually "decant" this supply, sorting and restocking it into a mobile medication cart.

This single, manual step is a critical point of failure. It is time-consuming, a major source of frustration for nursing staff, and, most importantly, it breaks the chain of custody, introducing a significant risk of human error.

A truly "closed-loop" medication system isn't just about electronic scanning at the bedside; it's about an unbroken physical logistics chain from the pharmacist to the patient. This is the Integrated Pharmacy-to-Patient Logistics Model, a strategy endorsed by leaders like the Canadian Society of Hospital Pharmacists (CSHP) for its proven ability to improve medication safety and system efficiency.

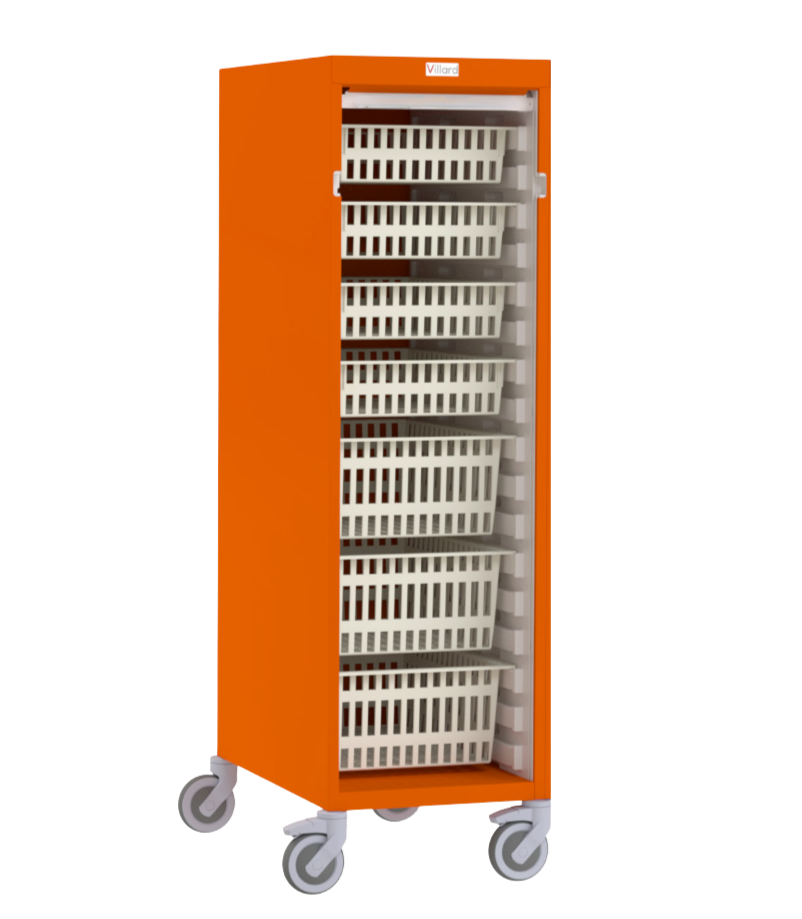

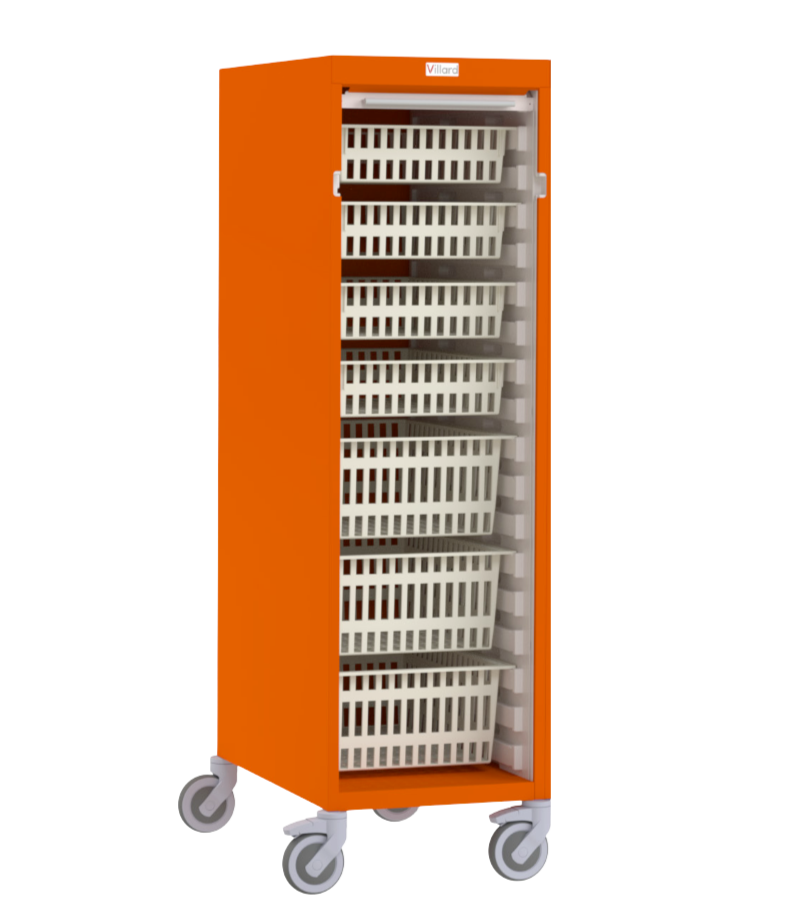

The Villard Eolis system is the physical infrastructure designed to execute this exact model, turning a fragmented process into a single, seamless, and secure workflow.

The Integrated Logistics Model: A Step-by-Step Workflow

This model is designed to eliminate the manual "decanting" step entirely. It relies on a standardized, modular system that connects the pharmacy directly to the point of care.

Step 1: Pharmacy Prepares the Patient-Specific Tray

The workflow begins in the central pharmacy. The pharmacist, working with the electronic health record (EHR), prepares a patient's 24-hour medications in ready-to-administer unit doses. These doses are placed into Villard Nominative Patient Bins.

This is where the system's flexibility becomes critical. The patient bins are equipped with adaptable sliding dividers. A patient with two small pills needs a small, defined slot. A patient with multiple vials, ampoules, and injectables needs a larger, custom-configured space. These dividers allow the pharmacy to create a custom, high-density bin for each patient's specific needs for that day, maximizing organization and eliminating wasted space.

Step 2: The Flexible Transfer Tray

These individual patient bins are then slotted into a single, modular Villard Transfer Tray (like the ISO 600x400 standard tray). This tray now contains a full, verified medication supply for multiple patients, all organized and prepared by pharmacy staff.

Step 3: The Transfer Cart (The "Middle Mile")

This fully-stocked transfer tray is placed into a secure Villard Transfer Cart. These carts are purpose-built for securely moving medications from the pharmacy to the nursing floor. With locking mechanisms and a durable chassis, the chain of custody remains unbroken during transport.

Step 4: The "Hot Swap" at the Distribution Cart (The "Last Mile")

This is the most transformative step. When the transfer cart arrives at the nursing unit, the nurse does not restock anything.

Instead, they unlock their Villard Eolis Medication Distribution Cart, pull out the previous day's empty tray, and simply swap in the new, fully-stocked transfer tray that just arrived from the pharmacy.

The nurse is now ready to begin their medication rounds in seconds. The cart is stocked, verified, and secured. The physical chain of custody is complete.

The Organizational Impact: Why an Integrated Chain Matters

This workflow is more than an operational tweak; it is a fundamental redesign of the medication system that delivers massive benefits to every stakeholder.

-

For the Nurse Manager: This system gives nurses their most valuable resource back: time. By eliminating the 30-60 minutes nurses spend each shift sorting and restocking carts, it reduces stress, cuts down on footsteps, and re-allocates that time to direct patient care. It also dramatically reduces the risk of administration errors by removing a manual step where medications could be mixed up.

-

For the Pharmacy Director: This model provides unparalleled control and efficiency. The pharmacy's careful preparation is exactly what reaches the patient, with no intermediate manual handling. It allows the pharmacy to work in efficient, predictable batches, improving inventory management and overall drug control.

For the Hospital Administrator: The business case is overwhelming. A single medication error can lead to a catastrophic adverse drug event (ADE), resulting in patient harm and massive legal liability. An integrated logistics system is a critical investment in patient safety. It reduces costs associated with medication errors, improves staff satisfaction and retention, and creates a more efficient, reliable, and defensible medication management process from start to finish.